The facility is aimed at heating houses, cottages and administration and accommodation buildings, equipped with forced or gravity hot water heating.

| Parameter | Forward-12,5 | Forward-16 | Forward-20 | |

|---|---|---|---|---|

| Rated heat output, kWh | coal | 13 | 17 | 21 |

| firewood | 12,5 | 16 | 20 | |

| Water maximum working pressure | 0,2 | |||

| Outlet water maximum temperature, no more than, t | 95 | |||

| Approximate fuel consumrtion - coke, anthracite (27500-32000 kJ/kg), kg/h | 1,8 | 2,6 | 3,1 | |

| Approximate fuel consumrtion - coal (17000-27000 kJ/kg), kg/h | 2,7 | 3,5 | 4,5 | |

| Efficiency coefficiency with coal, no less than, % | 75-80 | |||

| Approximate fuel consumrtion - wood, (moisture content no more than 15%), kg/h | 4,2 | 5,5 | 7 | |

| Efficiency coefficiency with wood, no less than, % | 72-77 | |||

| Heat exchange unit capacity, l | 22,5 | 24 | 26,5 | |

| Boiler negative pressure rarefaction, Pa | 4-25 | |||

| Outlet combustion products temperature, °C | 110 | |||

| Chimney diameter, mm | 140 | 140 | 150 | |

| The diameter of the fitted pipes, dm | 2” | |||

| Hydraulic resistance, no more than, kgs/сm2 | 0,09 | |||

| Boiler capacity regalation range, when burning anthracite should not exceed the limits, % | 50-110 | |||

| Heat turnover area, m2 | 1,07 | 1,16 | 1,25 | |

| Running cycle duration, when burning anthracite, no less than, h | 12 | |||

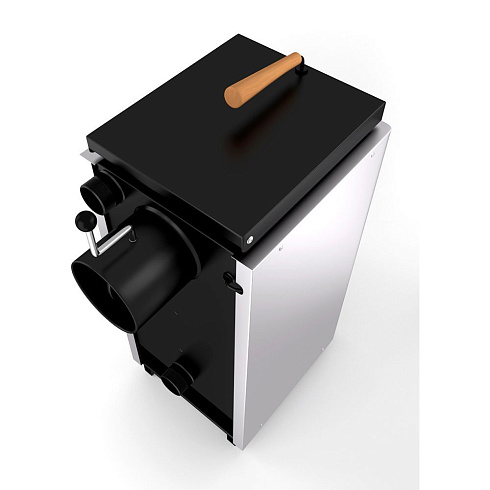

| Dimensions, no more than, mm | height | 892 | 892 | 892 |

| width | 365 | 365 | 400 | |

| depth | 570 | 570 | 580 | |

| Mass, no more than, kg | 70 | 73 | 78 | |